R&D: Certificate

(Research and Development Certificate)

Certified: In order to carry out the research stages – technologies of inventors and researchers of Saruj Bon Pei Company, according to the records of more than thirty years of production and implementation of industrial maintenance projects in the corrosion sector in land – sea – coastal areas and review of project records Findings especially in the sectors of oil – gas and petrochemical – aerospace industries and also the most severe environmental corrosion conditions of landfill pipes for fluid transfer in climates facing destructive factors. It hereby declares the results of the researches of 99, 98 and 97 years, both in the sections of successful cases, documented and based on records proving excellent qualities, and innovations and technologies, as described in this certificate. By reviewing production formulas and records, while reviewing the records process and enabling quality improvements, Additional measures in the R&D department under the license No. 20981 of the Tehran-Iran Province Industries and Mines Organization, as well as cases resulting in related operations with a record of 23 patents registered in Iran and two in the USPTO-USA and new achievements in application and Execution of products and based on tests performed by reputable laboratory institutions of the country in accordance with international standards, the items scored with the ability to produce and execute or monitor and execute training as follows will be notified to the relevant authorities. A: The results of the new tests are as follows: Includes a summary of the report of records and certificates issued by the industrial users of the country B: New uses of materials in the maintenance of land-sea industries -1. Introduction Considering that in the seabed section, the waters of different regions of the world, especially Venice, Italy, were observed:

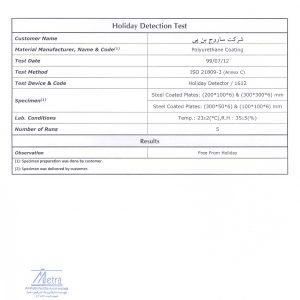

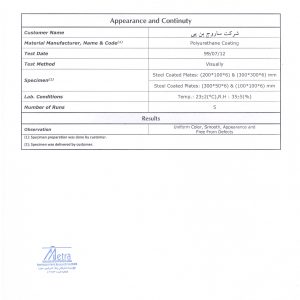

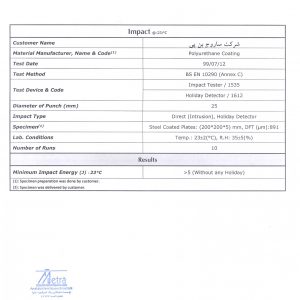

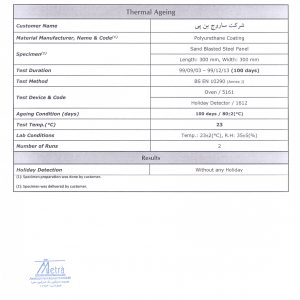

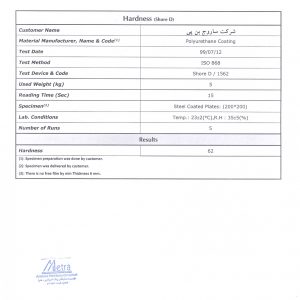

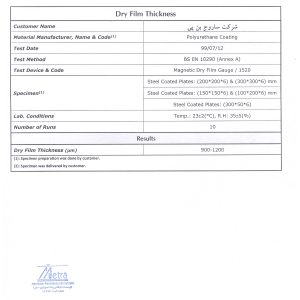

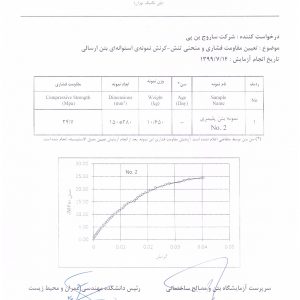

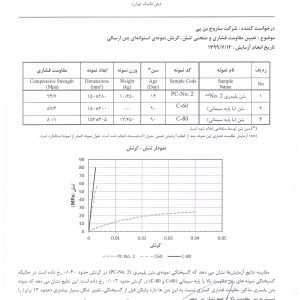

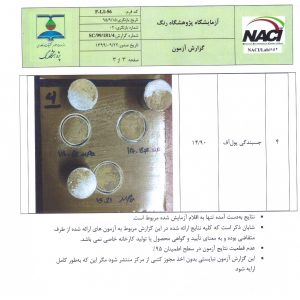

Replacing maintenance operations that ultimately did not meet with expected success. Application of Under water Coaling method Patents registered in the USA as well as inventions Nos. 61408 and 47837 under the name of Polymer Concrete Application Technology in Reinforcement of Pipes, Tanks and Underwater Sheath Coatings in Iran in order to Save Marine Structures, Especially Platform Bases: Commercial Pier And oil and gas and foreheads and repairs of concrete structures of bridges located on salt and fresh water, both in tropical and cold and icy regions, using Sarothane – Cancerete Polymer application technology and integration of special types of fillers suitable for different environments to perform work. Far more stable than has been the case so far. Explanation: In order to realize the technology of the subject, the R&D department of Saruj Ben Pei Company is ready to cooperate and participate in project management, production of necessary consumables with consulting engineers and offshore and offshore executives, especially for the maintenance of marine bases, including Venice declares Italy as well as the structures of offshore platforms in world waters that are subject to severe corrosion and wear and tear damage. The results of tests performed on reinforcing coatings with long life, especially zero moisture absorption – 280 kg / cm2 pressure and thirteen times higher than the strain behavior of standard concrete despite the possibility of underwater concrete structures from the surface of the water. Concrete in the presence of salt and fresh water, even in hot conditions, has provided new solutions for the maintenance of marine structures. 2. Thermal coatings Due to the fact that in some parts of the oil and gas, petrochemical and power plants, alternating temperatures, in addition to accelerating the performance of corrosion agents that shorten the life of structures, on the other hand to cover them to combat corrosion erosion, anti-corrosion coatings must be It should be done on their surfaces, but most common industrial coatings do not withstand static and run on hot surfaces, and if they do, their stability and durability will not be much. Sarothane-800AZ polymer coating type with the possibility of not needing to stop the industrial activity of units facing temperatures above one hundred degrees Celsius and even up to 300 degrees Celsius without the need for sandblasting and cessation of production activities, will be able to apply appropriate anti-corrosion coatings . This success can be applied to all industrial sectors of power plants and oil and gas and petrochemical industries. 3 – Making executive multipurpose polymers: Basically, in the manufacture of surface protection polymers, two types are made. But has no other repair uses. In order to overcome the two problems in cold applications that dry late and hot applications that dry quickly and do not allow local repairs, a type of Sarothane polymer with Various Curing application It has been made that corrects the low speed of cold execution and solves the hot problem of execution. Explain that the subject technology, in addition to creating executive facilities, especially in the welding section of pipelines and in cases where the cold polymer is able to capture and bake properly and quickly, does not reduce the required qualities and in accordance with standards, consumption of this type of polymer with Sarothane brand – W20 / 1100 is especially recommended for welding landfill pipelines with quality and speed of execution and without the need for special machines and equipment. 4- Construction of polymer concrete structures To build drinking water tanks and oil tanks that are necessary against the impact of destructive fragments and corrosion in harsh and accelerated erosion conditions – to prevent the penetration of corrosion agents on the reinforcement used in reinforced concrete even in submerged sea conditions and exposure to ions Chloride, whether as a protective layer of mortar with a thickness of about 2 to 10 cm on interior and exterior surfaces or as a complete structure of tanks, provides a new technology with long life, both economically and quickly. It is also possible to periodically repair and maintain the structures of drinking water reservoirs and storage tanks for oil derivatives. The use of this technology is recommended due to the hygienic results of the relevant material and structure for even drinking water and marine-coastal-power plant structures, especially in the Cooling Tower sections of cooling towers, as well as repairs and strengthening of water, oil and gas pipelines. May be. Production of polyurethane-epoxy polymers Industrial maintenance specialists, especially corrosion engineering departments and inspection organizations, are aware of the polymeric properties of epoxy and polyurethanes. They are considered necessary by consulting engineers, including the following: 1- Most polyurethanes, especially various types of component creams, have strong adhesion to surfaces compared to epoxies. are not. 2 – Moisture absorption of epoxies is more than polyurethanes, so in case of need for proper insulation, polyurethanes They are more suitable than epoxies. 3- Epoxy coatings often have high hardness and fragility, while in polyurethanes they have softening properties. Alternating and can be made for a variety of applications.

4 – Repairs of damaged sections can be done in polyurethanes, but in the case of epoxies is impossible or very

it is difficult.

Result: Special type of epoxy polyurethane polymer made by Saruj Benpi Company by combining the properties of both types of polymers and troubleshooting both products with adhesive properties without the need for primer – low moisture absorption and softness and non-brittle properties in both families ۀ Has made linear and circular possible.

The use of epoxy polyurethane polymers is recommended for all land and sea surfaces of industrial structures.

.

with respect

Ahmad Zolghadri – Chairman of the Board

Director of Research and Development